POTIS - ΡΟΜΠΟΤΙΚΑ

| Διαθεσιμότητα: | Σε απόθεμα |

Γερμανικής Προέλευσης

Μοιραστείτε το:

Specifications of Fast Food Döner Robots

- Doner Robots have been produced by using advanced mechatronics techniques.

- All cutting and cooking operations are done by a special computer software. This software has been developed with the information taken from the experienced doner masters that have been working in this field for many years.

- The doner robot cuts the doner by seeing it with the help of its digital camera and for this reason the surface of the doner doesn’t have to be flat.

- It cuts all kinds of doner meat perfectly in a standard.

- Thickness of cuttings can be adjusted upon demand

- Operating and using the robot can be learned in a short time thanks to its ease and remote control.

- Robots are durable since they have been produced with high quality materials.

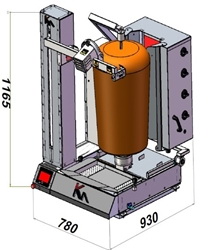

- Takes up less space thanks to the body designed as a whole

- Cleaning up the robot is easy as the parts touching the meat can be demounted easily.

Advantages of Fast Food Doner Robots

- It provides the opportunity to work around the clock.

- Thanks to its fast and standard cutting features an increase is provided in the number of portions and service speed.

- By means of its easy usage it minimizes the dependence on manual labor which requires cutting mastership and provides an increase in the quality of service.

- It is a center of attraction with its technological and hygienic appearance.

- It is such a productive machine that it amortizes itself in a very short time like 6 months.

| ROBOT 50 | ROBOT 80 | ROBOT 120 | ROBOT 220 |

|

|

|

|

Επίστροφή στην κατηγορία: ΡΟΜΠΟΤΙΚΑ